Why does drywall crack?

You just moved into your new house or reoccupied rooms that were recently renovated. The new drywall was painted and looked beautiful for the first six months. But after the winter thaw, you start to notice seams cracking and screws popping through the paint. Perhaps your first inclination is to blame the contractor who did the work. While it is true that poor construction methods can cause screw pops and cracked drywall joints, it may be good to understand some of the many reasons why drywall cracks and screws pop. Many times, it is not at all related to the drywall installation process.

The seam where two sheets of drywall meet is a weak point in the wall. Drywall tapers use mud and tape to give strength to the joint. Drywall tape can be likened to a band-aid for the fault line. Then layers of drywall mud are added to feather the seam smooth with the rest of the wall. When a house settles or walls move, cracks may indicate either weakness in the joint or movement that exceeded expectations.

The wrong type of drywall mud was used

One reason drywall cracks is because the wrong type of drywall mud was used when taping the seams. Some drywall mud has more adhering ability and should be used when taping drywall, whereas other types of drywall mud should only be used in finishing. Some drywall mud products are intended only for second or third coats. You can read much more about different types of drywall mud, and when they should be used.

Mesh tape was used with all-purpose mud

Some drywall tapers say that mesh tape should never be used in drywall taping because it is not as strong as paper tape. Other drywall tapers say that mesh tape is fine as long as it is used with quick set drywall mud (SHEETROCK® BRAND easy-sand or Pro Form® BRAND stay-smooth joint compounds). We have found mesh drywall tape to work well as long as it is bedded-in with quick set drywall mud (hot mud). Using an all-purpose or lightweight drywall mud with mesh tape often results in drywall cracks.

Why does drywall corner bead crack?

Cracks sometimes develop where drywall corner bead is installed. This is often due to improper installation. There are different types of corner bead and each type has specific requirements for installation.

For example, vinyl corner bead can be installed with spray adhesive but if the wrong type or not enough adhesive is used, cracking may occur when the building settles. If staples are used to install vinyl corner bead and it is not done properly, it can cause cracking later on. When installing metal corner bead, screws or nails are required to give the corner sufficient strength. However, if not enough fasteners are used or they are spaced too far apart, it can lead to cracking during settling.

Drywall contractors have differing opinions as to what is the strongest method for installing corner bead. Many feel that the paper-faced ("tape-on") corner bead is the strongest and least prone to cracking. We have found that in situations where you must ensure a very strong corner that prevents cracking in the future, a paper-faced corner bead installed with an all-purpose drywall compound is the best option. See also how to coat corner bead?

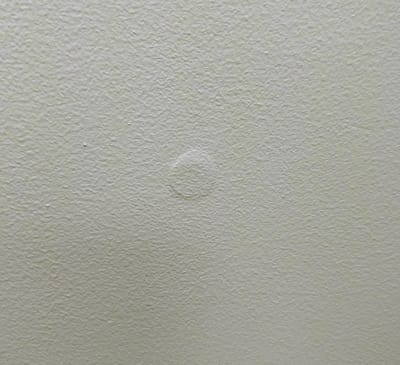

Causes for nail and screw pops

Another common problem with drywall is nail pops. Nail pops occur when the head of a nail "pops" through the paper of the drywall and creates a separation in the paint. They look like small round circles the size of the nail head. This usually occurs within the first year after a drywall job has been completed.

Drywall screws or nails are used to secure drywall to the studs below. The head of the fastener puts pressure against the paper on the surface of the drywall. If the screw head goes too deep and busts through the paper into the gypsum layer below, it no longer can hold the sheet of drywall firmly. When installing drywall, Drywall Hangers will at times use construction adhesive on the studs below and then use nails or drywall screws to hold the sheet until the glue has time to dry. When this is done it reduces the number of nail pops. However, this is not a perfect prevention solution.

Not all drywall cracking is caused by bad installation methods

All this being said, the strength of drywall tape is limited. Construction adhesives, fasteners, drywall tape, and corner bead all have limited strength. If a house settles and walls move to any great degree, no amount of tape or glue will keep it from cracking.

Many times significant cracks in drywall are the result of engineering deficiencies when designing the building. Engineers expect settling and movement in a building over time. They often design solutions to mitigate major movement and allow a building to move slightly while not allowing it to break. Well-placed expansion joints are a good example of an engineering solution for expected building movement. If cracks develop that are obviously beyond the scope of a drywall contractor to completely remedy, it may be best to look to other solutions to prevent the movement so that when the drywall cracks are repaired, they will not crack again.

Drywall Tape can't prevent all cracking

When cracks develop in a house, they usually run along high-stress areas. Areas above doorways and windows or areas over beams that span long distances would be considered high-stress. When a building moves, even slightly, extreme pressure is placed on these areas since they are load-bearing zones.

What causes movement in a building? There are many factors and not all movement can be eliminated. However, natural movement caused by building settling should be accounted for in the design phase of construction so it can be managed by construction materials and methods. If any part of the house was built on fill dirt it will have a greater possibility of settling. Most new houses will settle within the first year. Good drywall techniques will limit the occurrence of cracks and nail pops.

Conclusion

In summary, cracks that run along high-stress areas of door and window headers or ceilings with long open spans may be a result of the building settling. There is probably nothing the drywall finisher could have done to prevent it. Extensive cracking especially in areas that are not high-stress points may indicate that there was some delinquency on the part of the Drywall Hangers or Tapers. Most Drywall companies will be willing to repair minor cracking or nail pops within one year of the finish of a project.