Drywall t-Square

A drywall t-square is essential for cutting and installing drywall panels. It is used primarily to provide a straightedge along which to cut drywall using a drywall utility knife. Below are a few tips to look for when buying a drywall t-square.

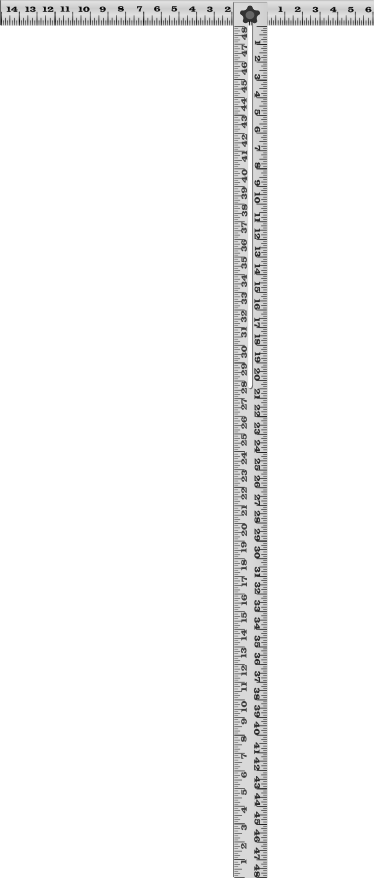

Drywall t-squares are two pieces of metal connected at right angles to one another. The shape of the two pieces of metal creates a capital T-shape, thus the name. The two pieces of metal create a 90° angle just below the crossbar of the T-shape. This 90° angle is essential to ensure that the cut edge (butt joint) is exactly 90° from the bound edge (drywall seam) when cutting drywall panels.

T-squares are generally made out of aluminum. Aluminum is preferred because of its lightweight and resistance to rusting. Since most drywall panels are 48 inches tall, standard size t-squares are 48 inches from top to bottom, though other lengths can be found. 54-inch drywall sheets are sometimes used when hanging drywall in rooms with tall ceilings. The increased width prevents unnecessary seams if the ceiling is higher than 8 feet and less than 9 feet. When using 54-inch panels, a 48-inch t-square falls short so longer t-squares can be used however these longer t-squares are useless for cutting standard 4-foot sheets.

There are a few features to look for when buying a drywall t-square. The long edge of some t-squares is made with one-eighth or more inch thick aluminum. This thicker metal creates a safer straight edge than thinner models of just one-sixteenth of an inch thick metal. A thicker straight edge is safer because it prevents the utility knife from slipping off the cutting side of the t-square and sliding across the metal face of the t-square.

Another feature to look for is an adjustable height. As just mentioned, most t-squares are 48 inches tall to match drywall panels. Some have an adjustable screw where the two pieces of metal come together. This allows the crossbar of the t-square to slide vertically along the long edge and create a shorter t-square. For example, if you have an already ripped panel 30 inches in width, a 48-inch t-square is difficult to use. An adjustable t-square can quickly be the short end for this one cut and then returned to full height for other panels. Ideally, you would like a 54-inch tall adjustable t-square that can be used for cutting all sizes of drywall panels.

A drywall t-square is primarily used to cut full sheets of drywall at right angles. However, a professional drywall hanger makes use of his t-square in other ways. At times, angle cuts are required to match vaulted ceilings or other architectural designs. The 90° angle of a t-square can be used as a reference on the wall against which to determine the proper angle cut. A drywall hanger's ability to use this tool and calculate the intricate angles needed, speaks to his ability as a carpenter, including his math skills.

Drywall t-squares are an essential tool for a drywall hanger. When buying a t-square look for one made of thicker metal and adjustable height.